Las Cruces Residents - Learn Lean Six Sigma’s History Here

Contact Us

Lean Six Sigma is a methodology that has been used in manufacturing, businesses, and personal projects for the past decade, but its inception goes a couple of decades back due to how it originated and why. The basics of LSS are focused on how it helps practitioners improve their processes and reduce waste. Lean Six Sigma can still be useful regardless of the circumstance, and although everything came from the need for manufacturing and improving processes, there’s a lot to learn about its history. At Lean Six Sigma Curriculum for Las Cruces High school Students of New Mexico, our experts can offer you all the information about the method’s history and origin.

Lean Six Sigma is a mixture of Japanese management principles. However, it is primarily a combination of Lean and Six Sigma, which originated for different needs, but all of them would aim at the final result of continuous improvement.

Before we can proceed, it is important to make clear that LSS is not Japanese, despite its influence from Japanese methods.

Kaizen is the Japanese influence on the Lean Six Sigma methodology, and this method encourages cooperation and commitment to continuous improvement. However, they are not the same when you start to compare them.

As they were created before LSS, we should focus on Six Sigma and Lean methods. Each contributes at its own level and has structures that can be combined to improve LSS.

Six Sigma and Lean can all be traced back far before our main methodology or with some years of difference.

How Did Six Sigma & Lean Begin?

It is important to understand the differences between Six Sigma and Lean, as LSS is not a simple combination of the two.

Because of its structure, Lean is also known as “Lean thinking.” It helps businesses and industries think about customers and improve their processes.

Lean can be traced back to Toyota and how it was integrated into Toyota Production System. John Krafcik was once a student at Toyota, and he was looking for a name to describe the TPS system that he had developed at the time.

He wrote down the differences between Toyota’s system and traditional mass production on a whiteboard. He concluded that Toyota’s system needs less of everything to create value. This holds true for all Lean concepts, and thus, Lean was quickly established by his conclusion and studies.

Today, Lean is focused on reducing waste and non-value-added activities.

Lean is built upon its own principles and foundations. Understanding the customer is crucial to understanding the process waste stream and its value streams based on resources that are needed. Although it may sound like Kaizen, it’s not.

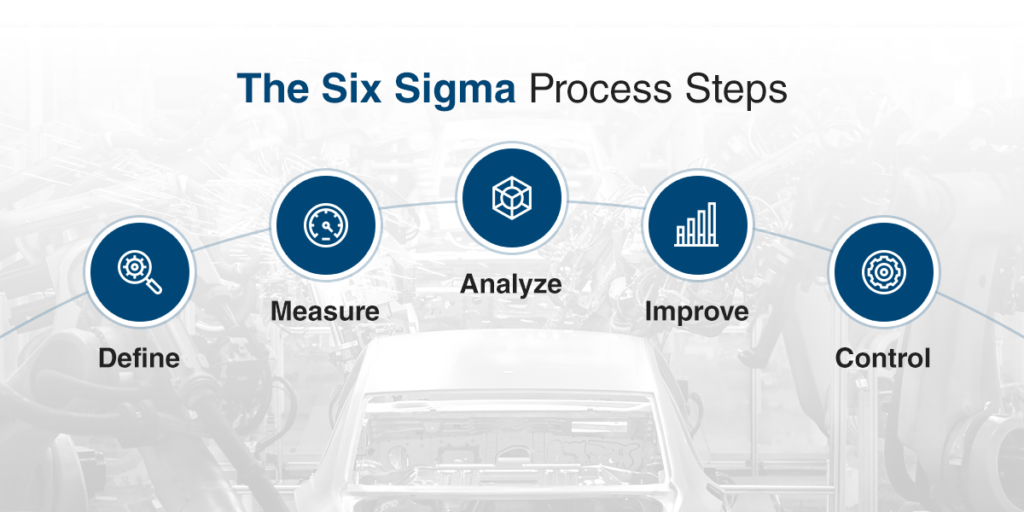

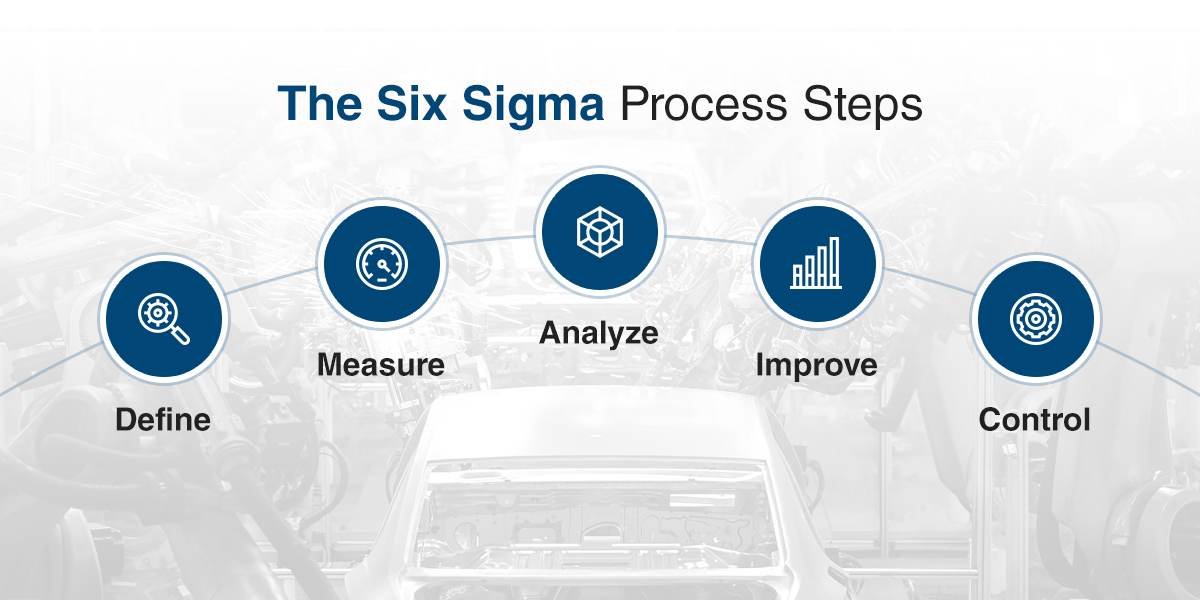

Six Sigma, an American-based methodology that dates back to the 1980s, will be next. Six Sigma was created by Motorola and is the second methodology that influences LSS and the structure it follows to help companies today.

Motorola was far from being a formidable competitor for foreign companies in its early years. Thus, Motorola’s founder Bob Galvin had set a goal to achieve tenfold growth in five years.

The plan was focused on global compatibility, participative management, quality improvements, global competition, and cooperation. Motorola quickly adopted six Sigma as the standard for all business processes since it increased cycles and produced better results.

Both approaches recognize that success can only be achieved through change. Six Sigma is a great addition to the Lean process, and LSS was born when both the Lean and Six Sigma principles were combined.

Each technique should maximize its potential by following the existing structure, setting the basics, and adding value.

What’s Lean Six Sigma?

LSS has been used in many ways throughout history. It is designed to increase productivity and efficiency and reduce waste.

To have a clearer view and understanding, let’s review: Lean allows employees and companies to better understand customers and prioritize customer needs. To achieve perfection, they can focus on the company’s value stream. Six Sigma is committed to excellence and a culture that encourages efficiency and clean operations.

When you translate this into LSS and focus on the results you can achieve, all LSS practitioners and those who implement it can:

- Learn how to reduce waste.

- Increase efficiency.

- Reduce errors.

- Reduce your risk.

- Time management.

- Lower costs equal higher revenues and better wages.

- Motivate employees.

- Innovation and leadership are two fundamental concepts that can be established in a company or individual’s mind.

Learn Lean Six Sigma in New Mexico

Lean Six Sigma Curriculum Pros of Las Cruces is available to assist you. This method is well-known in the city, and our goal is to allow students of all levels to learn how to integrate LSS into their everyday lives and business processes, or regardless of the path they choose for personal growth.

We want you to reap all the benefits, so let our team help by requesting our training and certification.